Mosbuild-Buildex 2015 Moscow

Date : 31 Mar – 3 Apr 2015

Borsche Textile will be exhibiting at mosbuild-buildex 2015 moscow,

from 31 Mar – 3 Apr 2015, at PAVILION 2.3,

where We will present our new collections.

We look forward to meeting you soon.

Our product groups

1. 100% Inherently Flame Retardant Fabrics pass M1 standard

2. FR Blackout Foam coating Fabrics pass BS 5867, NFPA 701 standard

3. FR Foam coating Fabrics pass BS 5852 standard

4. Flame Retardant Curtain Fabrics

5. FR Blackout and Dim out Fabrics

6. FR hospital cubical curtain fabric

7. Easy to clean fabrics

8. Furniture fabrics

9. Drapery fabrics

10. Jacquard fabrics

Date : 4 May – 7 May 2015

Borsche Textile will be exhibiting at Frankfurt, Germany from 04th- 07th of May at HALL 4.1 D92A,

where We will present our new collections.

We look forward to meeting you soon.

Our product groups

1. 100% Inherently Flame Retardant Fabrics pass M1 standard

2. FR Blackout Foam coating Fabrics pass BS 5867, NFPA 701 standard

3. FR Foam coating Fabrics pass BS 5852 standard

4. Flame Retardant Curtain Fabrics

5. FR Blackout and Dim out Fabrics

6. FR hospital cubical curtain fabric

7. Easy to clean fabrics

8. Furniture fabrics

9. Drapery fabrics

10. Jacquard fabrics

APOLLO-THE SUREST WAY TO MEET PRODUCT PERFORMANCE STANDARDS

The highest technology light fastness tester "APOLLO" which is not only does it simulate sunlight faithfully, it also replicates a wide range of temperatures and humidity levels in closely controlled conditions-essential when you need to predict a fabric’s performance in real-life situations.

The highest technology light fastness tester "APOLLO" which is not only does it simulate sunlight faithfully, it also replicates a wide range of temperatures and humidity levels in closely controlled conditions-essential when you need to predict a fabric’s performance in real-life situations.

As you strive to develop fabrics and materials that perform well in different light conditions. Only the latest testing technology can give you real confidence in your products and that they will satisfy your customers and meet national, international and retailers’ standards.

Conform to the standard as below:

1.AATCC TEST METHOD 16-2003

2.AATCC TEST METHOD 169-1995

3.ASTM G 155-00a

4.ISO 105 B02 1999 UNDER HIGH EXTREME CONDITION AND EFFECTIVE HUMIDITY

5.ISO 105 B02 1999 UNDER LOW EXTREME CONDITION AND EFFECTIVE HUMIDITY

6.ISO 105 B02 1999 NORMAL CONDITION

7.ISO 105 B02 1999 AMERICAN STANDARD

8.ISO 105 B04 1994

9.ISO 105 B06 1998 CONDITION SETUP NO.1

10.M&S C9 2002

11.M&S C9A 2002

MICROSCOPE

In this field of textile which needs more and more high technology equipments for the skills of development.

In this field of textile which needs more and more high technology equipments for the skills of development.

This M1 Microscope with multi-function which is able to develop very precisely finished products.

In the meantime, the microscope as such is able to assured whole complete producing process without pollution and to hold good quality as usual.

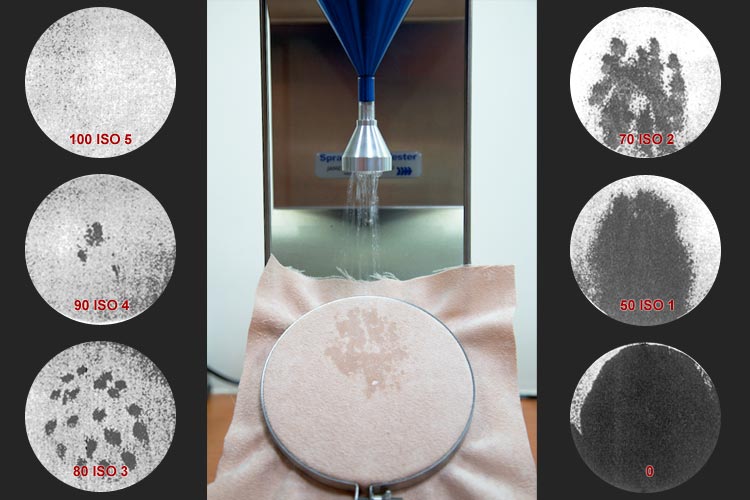

TESTER 513

The Spray Test is a simple method to determine the resistance of any fabric. A specified volume of distilled water is sprayed centrally onto an inclined test specimen. Stringent quality control of the nozzle hole pattern, combined with accurate height setting above the specimen, ensure a consistent spray flow and formation, critical to the requirements of the international standards.

The Spray Test is a simple method to determine the resistance of any fabric. A specified volume of distilled water is sprayed centrally onto an inclined test specimen. Stringent quality control of the nozzle hole pattern, combined with accurate height setting above the specimen, ensure a consistent spray flow and formation, critical to the requirements of the international standards.

The spray rating is determined by comparing the appearance of the tested specimen with descriptive standards and photographs.

The AATCC Spray Test Rating Chart is available for this purpose.

100 - No sticking or wetting of the specimen face.

90 - Slight random sticking or wetting of the specimen face.

80 - Wetting of specimen face at spray points.

70 - Partial wetting of specimen face beyond the spray points.

50 - Complete wetting of the entire specimen face beyond the spray points.

0 - Complete wetting of the entire face of the specimen.

Standards are as below:

EN 24920/ISO 4920

EN 14340

AATCC 22

M&S P23

Fabric Knowledge is here!!!

Q1 : What does Fire-resistant stand for?

A: Fire-resistant means fire safety. There are various technical testing methods to exam how safety the fabrics aer. For example, M1 is commonly used in France and Spain, as British Standard(BS) for the United Kingdom. B1 is the method used in Germany, and Class Uno is applied in Italy.

In order to meet the needs of the market, Borsche Textile Company has purchased quite a few testing machines to provide the most approriate fabrics for its customers.

Q2 : Why is Blackout so popular?

A : Blackout stands for its name, to block out the lights. However, it has its degree of darkness, ranging from completely 100% to semi-darkness. If we are talking about curtains in a pubic entertaining areas, such as cinema, the basic requirement is 100% blackout. Different people might appreciate various degrees of darkness at home or at the office; hence, it is widely welcomed.